The has FDA has finalized its COVID-19 vaccine approval, and the formidable task of vaccinating an entire country has begun. Transporting and storing the new vaccines will not be an easy task, and ICP DAS USA is here to provide cost-effective solutions to manage the ultra-low temperature freezers that the vaccines require. According to the Thomasnet.com, Moderna’s vaccine must be stored long-term at 20 degree Celsius. ICP DAS USA has a proven track record of providing reliable cold storage control and monitoring solutions for agriculture, transportation, and laboratories.

Transporting the Vaccines Safely

For vehicle monitoring, ICP DAS USA’s DL-100S-E-W can be used to record temperature, humidity and dew point information. This is a standalone Datalogger. For more remote monitoring in real-time, it supports Modbus TCP protocols so that a Modbus master device can read real-time data. This connection can be used to display the current temperature using the TPD-283U-H that an operator can read and monitor. It also has a relay output to trigger the cooling condenser unit start/stop if the temperature goes outside an acceptable range; and it will log which probes go out of the temperature range and when. The data stored in the module can be downloaded and exported in CSV format. The housing is rated at IP66 for use in rugged and hard environments.

How to Keep the Vaccines Safe in Ultra-Low Temperature Freezers

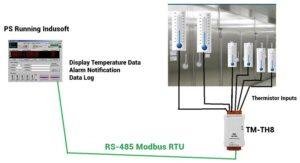

ICP DAS USA’s remote temperature data acquisition modules such as the TM-TH8, an 8 channel thermistor Modbus RTU data acquisition module, can be used to capture data from thermistors. The temperature sensors of 8 locations can be wired to this module and monitored using Modbus RTU protocol. ICP DAS USA’s ET-7015 is a 7 channel Modbus TCP Data Acquisition module that can be used to capture sensor data from thermistors. The temperature data from up to 7 sensor channels can be read using Modbus TCP protocol. Each freezer or walk in refrigerator can be monitored and controlled from a central control enter, allowing operators to monitor freezer status from multiple locations at once, while automatically logging irregularities.