In the Packaging Industry, Equipment / Machinery usually involves rotational motion. This includes such movements or procedures such as Indexing, Conveyance, Gluing or Sealing, Flying Cuts as well as other Machine Functions that offer rotary axis. In order to control all these Packaging procedures and maintain accuracy a Rotary Encoder is needed.

Tri-Tronics offers to this Industry many options that will work for several applications, the most popular or demanded Encoder series used in the Packaging Industry are as follows:

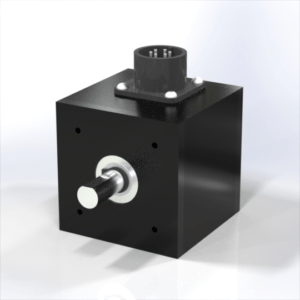

Shaft encoders are planned for direct coupling to a device shaft. Thus they generate a specific output pulse for each revolution of that Device shaft. To adapt or adjust to angular and rotational misalignment between two shafts;  Tri-Tronics recommends a flexible shaft coupling or similar. Direct Mount is not recommended and may minimize or reduce Bearing Life. The R20 incorporates heavy duty bearings that can be used in driving a timing shaft and/or pulley syst.em

Tri-Tronics recommends a flexible shaft coupling or similar. Direct Mount is not recommended and may minimize or reduce Bearing Life. The R20 incorporates heavy duty bearings that can be used in driving a timing shaft and/or pulley syst.em

HS Series ft-to-shaft misalignme

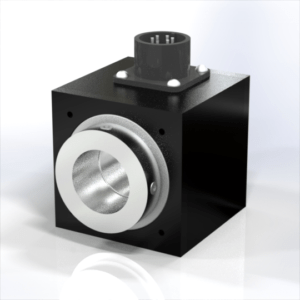

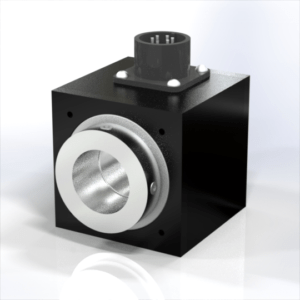

Hollow shaft encoders are designed with either a through-bored shaft or a blind-bored shaft, and intended to mount directly onto a motor or other shaft.  This eliminates the need for a shaft to shaft coupling and mounting adapter, resulting in both space and cost savings. The encoder “floats” on the motor shaft. A tether or flexible mounting bracket prevents the encoder from turning, yet accommodates shant.

This eliminates the need for a shaft to shaft coupling and mounting adapter, resulting in both space and cost savings. The encoder “floats” on the motor shaft. A tether or flexible mounting bracket prevents the encoder from turning, yet accommodates shant.

| The model RS and HRS is an optical encoder with standard 2¼” cube shaped housing that is electrically interchangeable with most cube style encoders on the market. It is designed to mount directly on an existing shaft. A flexible mounting bracket or other type of tether allows the encoder to float on the shaft without rotating. The number of pulses per revolution is determined by setting configuration switches accessible through an access port near the connector. Any one of a predefined set of pulses per revolution are available. |