BOA Spot XL vision sensors offer simplicity and affordability for error-proofing, identification and guidance applications.

The BOA Spot XL vision sensor combines the power and flexibility of a BOA vision system with integrated optics, lights and easy-to-use setup software to deliver high value capabilities at a low cost of ownership.

This highly versatile sensor is fully equipped with vision tools and capabilities suiting a range of industrial applications for manufacturing, logistics and general automation. BOA Spot XL tools can be combined and used multiple times to solve simple or complex inspection tasks that go well beyond the capabilities of traditional sensors.

FEATURES AND BENEFITS

» Fully integrated vision solution includes software, processing, lighting and optics

» Easy setup for the first time or experienced vision users

» Versatile toolset supports widespread applicability

» Integrated factory protocols make it easy to communicate with 3rd party equipment

» Offers features and capabilities normally found in higher-end vision solutions

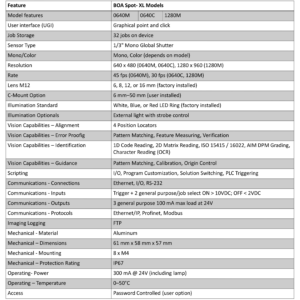

» Standard and high resolution sensor options

» M12 or C-mount lens options

» White, Red, Blue or external light options

» Flexible mounting options

» Hardware or software job switching

» Remote monitoring and control

» FTP image transfers

» Built for factory environments

» Low cost of ownership

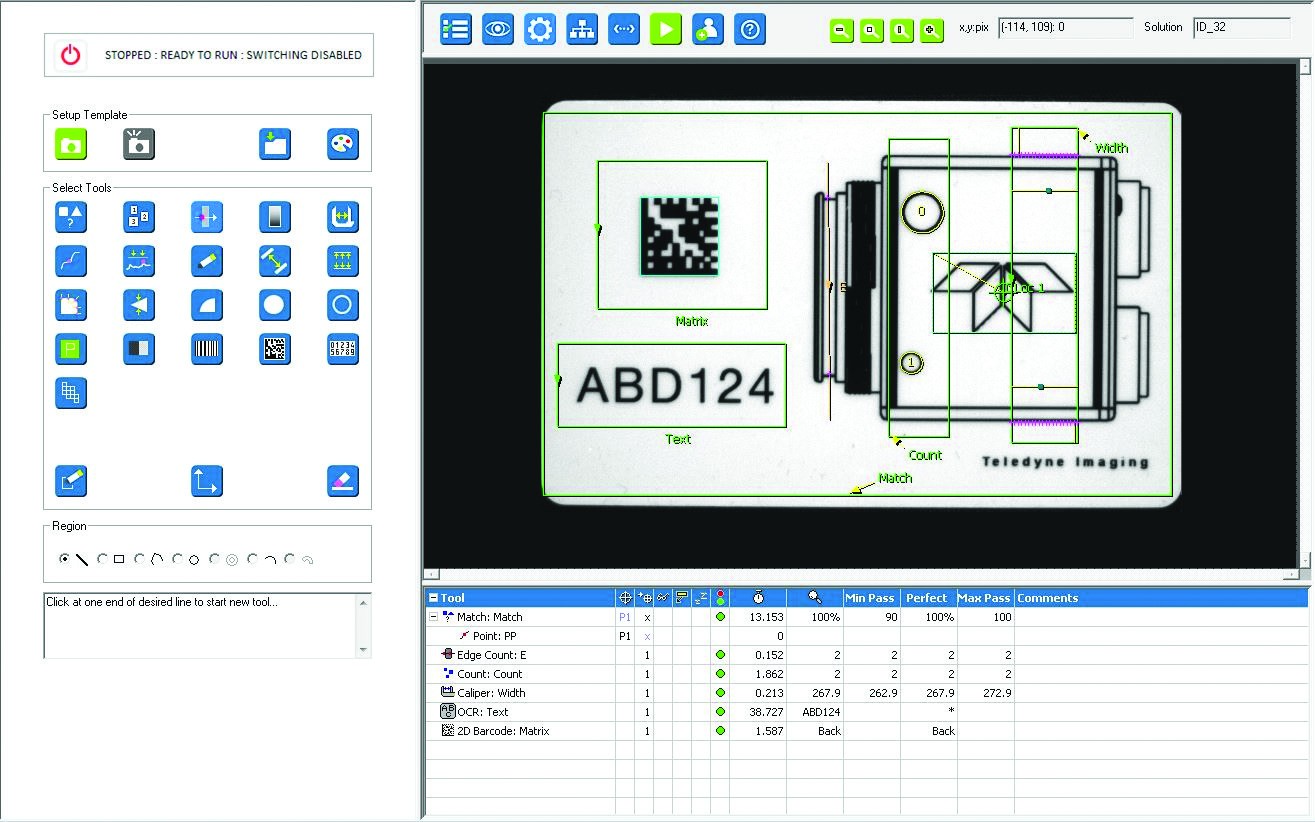

USER INTERFACE

The BOA Spot XL User Interface is quick to learn and applicable for both novice and expert users alike. Guided setup is supported on the top navigation bar, while the left and bottom panels are used for function-specifi c setup, advanced control and status reporting. The interface offers a full complement of features for both setup and runtime operation. The application software is resident on the sensor and the user interface is conveniently accessed from the device webpage.

TYPICAL APPLICATIONS

The BOA Spot XL vision sensor offers an advanced tool set suitable for a range of industrial applications.

ESPECIFICACIONES

Contáctanos

ventas@logicbus.com | soporte@logicbus.com | 55-5431-67-18 | Iniciar conversación